Human experience, trial and error, and meticulous planning based on prior successes were the main drivers of manufacturing in the past. Over time, factories relied on highly qualified engineers, technicians, and designers to enhance their products. Although this approach was effective, it was frequently costly, slow, and constrained by human creativity.We are starting a new age today. In manufacturing, generative artificial intelligence (AI) is a potent technology that is revolutionizing the design, production, and optimization of products.

Giving people a tool that can think, learn, and create alongside them is the goal here, not replacing them. Generative AI can come up with new ideas that even experts might not think of, rather than just following directions.

From designing lighter airplane wings to optimizing car engine components, generative AI is becoming a trusted partner for engineers and manufacturers worldwide. Let’s explore how it works, why it’s important, and what the future holds for this revolutionary technology.

Understanding Generative AI in Manufacturing

Let’s first define generative AI in manufacturing before moving on to the future.

Artificial intelligence that can produce as well as analyze is known as generative AI. In manufacturing, it takes a set of objectives, guidelines, and limitations (including budget, production processes, material limits, and strength requirements) and then produces a number of design options that satisfy those requirements.

For instance:

An engineer may require a bracket that is as light as possible while still supporting 100 kg.

The engineer enters the criteria into a generative AI algorithm rather than manually drawing concepts.

The AI creates dozens of bracket designs in a matter of hours, each one optimal for material usage, weight, and strength.

The engineer can then choose the best option, test it virtually, and quickly move toward production. This process replaces weeks of manual work with a much faster, data-driven approach.

Why Generative AI in Manufacturing Matters for the Future

The manufacturing sector is always under pressure to produce goods more quickly, more affordably, and with better quality. These issues are directly addressed by generative AI in manufacturing.

Velocity

It can take months to develop a traditional product. By simultaneously generating hundreds of design choices, generative AI can cut this down to days or even hours. This enables businesses to proceed swiftly from idea to prototype.

Savings on expenses

AI-generated designs frequently maintain or enhance performance while using less material. This improves resource utilization and directly reduces production costs.

Sustainability

AI can greatly cut waste by optimizing for material efficiency. This is a significant benefit for firms trying to achieve environmental goals. An AI-optimized auto component, for instance, might consume 30% less aluminum, resulting in less mining, less energy to produce, and fewer emissions while shipping.

Worldwide Competitiveness

Early adopters of generative AI can maintain their competitive edge by providing superior products at reduced prices. This edge is crucial in a global market that is changing quickly.

Changing Manufacturing Processes

The future of generative AI in manufacturing goes far beyond designing parts. It’s influencing the entire production process, from factory layout to supply chain management.

Production Line Optimization

AI can analyze how machines, workers, and materials move through a factory. It can suggest changes that reduce downtime, speed up production, and improve safety.

Predictive Maintenance

Instead of waiting for machines to break down, AI can predict when maintenance is needed by analyzing vibration, temperature, and performance data. This reduces costly downtime.

Custom Manufacturing

Mass production is giving way to mass customization. Generative AI can instantly adjust designs for unique orders — whether it’s a medical implant tailored to a patient or a customized car part for a client.

Supply Chain Planning

AI can forecast demand for products, optimize delivery routes, and reduce excess inventory. This helps companies save money and respond faster to market changes.

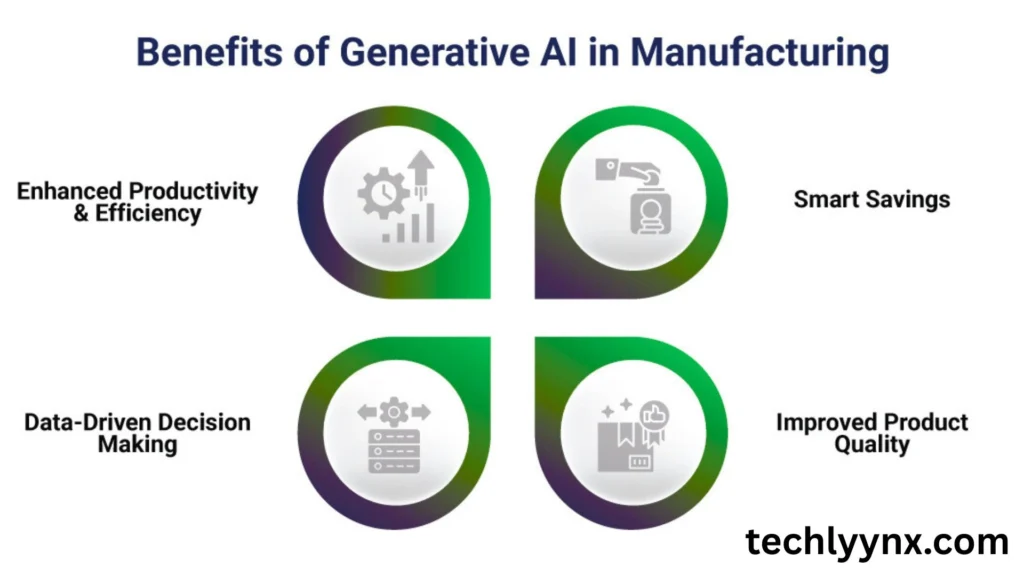

Benefits of Generative AI for Manufacturers

Generative AI offers far more benefits than just speed and cost effectiveness.

Design Freedom: AI investigates forms, shapes, and structures that human designers could never consider.

Improved Performance: AI-optimized designs frequently exhibit superior durability and strength-to-weight ratios.

Rapid Prototyping: AI concepts can be turned from concept to tangible prototype in a day when combined with 3D printing.

Resource Efficiency: Reducing waste results in cheaper expenses and a lesser environmental impact.

Competitive advantage: Businesses that use AI are able to respond to consumer demands and product releases more rapidly.

Real-world example: Airbus redesigned a cabin divider for its A320 aircraft using generative AI. As a result, the construction is 45% lighter than it was initially, which saves fuel and lowers pollutants.

The Road Ahead

Generative AI in manufacturing is only getting started. A number of trends are anticipated to influence its future in the upcoming years:

Combining Robotics with Integration

AI-generated designs will be given straight to robotic systems, which will be able to produce them with little assistance from humans. Production will become even more accurate and swift as a result.

More Intelligent Digital Twins

AI will be able to model changes before they occur in real life by digitally recreating entire factories. Without interfering with production, manufacturers can test new product lines, procedures, or layouts.

Real-Time Modifications to the Design

AI will have the ability to modify designs in real time in response to production line input. AI might immediately modify the design to preserve quality if a machine begins to produce parts with a small amount of tolerance.

Innovation that is Sustainable

Environmentally friendly alternatives, such as recyclable materials and energy-efficient production techniques, will be given even greater attention by generative AI.

AI-Human Cooperation

AI will work with engineers rather than in place of them. While AI manages intricate computations and optimization, humans will provide creativity and insight.

Final Thoughts

Generative AI has already arrived and is influencing the way that goods are created. Generative AI in manufacturing is becoming a crucial component of the sector’s future by assisting businesses in improving designs, increasing productivity, and cutting waste.

The manufacturers of the future will be those who adopt this technology now. When AI-powered rivals introduce smarter, more effective, and more sustainable solutions to the market, those who are hesitant run the danger of falling behind.

Collaboration between human creativity and machine intelligence will be the foundation of manufacturing in the future, and it’s a future to be enthusiastic about.