The manufacturing industry is undergoing a change. Large, noisy machines and human labor were the mainstays of factories in the past. Even while these old-fashioned factories were useful to us, they frequently had issues with waste, inefficiency, excessive costs, and downtime.The emergence of smart factories—modern production facilities that employ cutting-edge technology to increase productivity, flexibility, and sustainability—accompanies the current era of Industry 4.0.

However, what are smart factories and how do they operate? Let’s put it in plain language.

What is a Smart Factory?

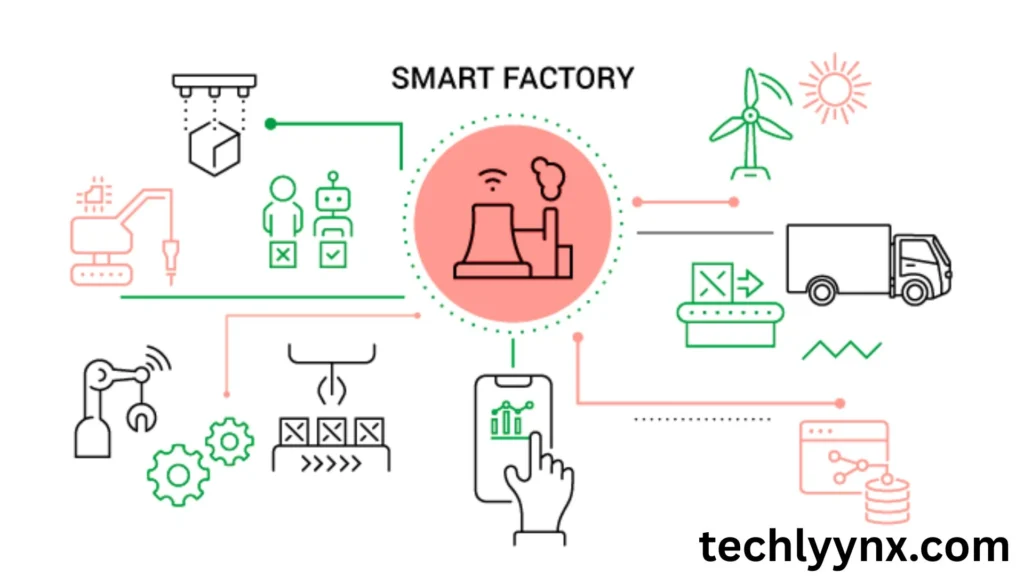

A smart factory is a production system that prioritizes digitalization, automation, and high connectivity. Smart factories use automation, artificial intelligence, and real-time data to make decisions independently, in contrast to traditional factories that mostly rely on human intervention.

Consider a smart factory as a self-driving car, whereas a typical factory is as a human-driven vehicle. Without continual human supervision, it is able to perceive its environment, learn from data, and take corrective action on its own.

Automation is not the only aspect of smart manufacturing. They deal with intelligence—factories that are able to anticipate, learn, and keep improving their operations.

Key Technologies Behind Smart Factories

Smart factories combine several cutting-edge technologies. Each plays a critical role in making production faster, safer, and more reliable:

- Internet of Things (IoT): Sensors and devices are placed on machines to collect real-time data about performance, temperature, energy use, and output quality.

- Artificial Intelligence (AI): AI systems analyze the data, spot inefficiencies, and even predict when a machine is likely to fail.

- Robotics & Automation: Robots perform repetitive, dangerous, or highly precise tasks, reducing the need for manual labor.

- Big Data & Analytics: Large amounts of data are processed to find trends that help managers make better decisions.

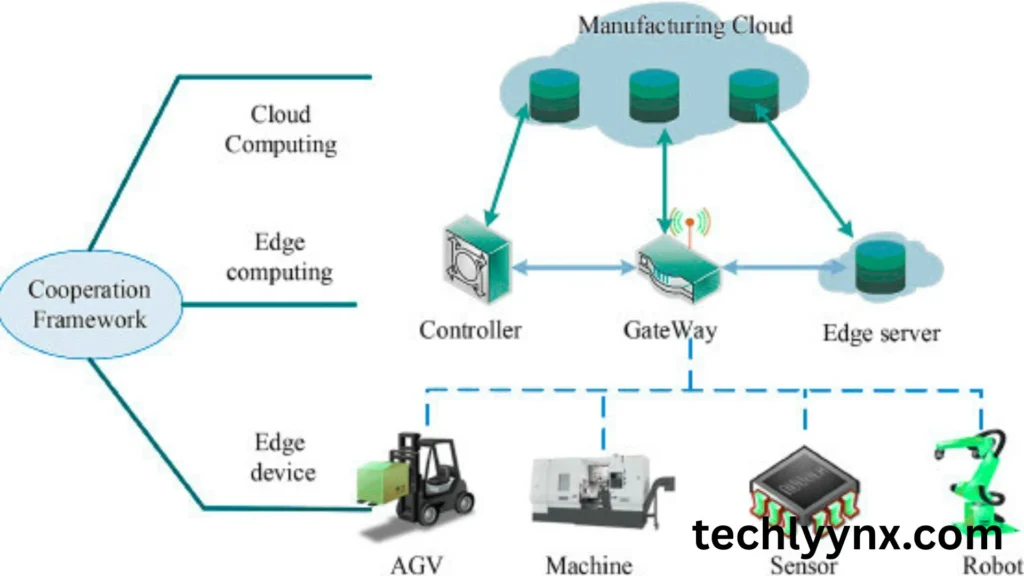

- Cloud & Edge Computing: These allow factories to process and share data quickly, no matter where they are located.

- Digital Twins: A digital copy of a machine or process lets engineers test new ideas virtually before making changes in the real factory.

- 5G Connectivity: Ultra-fast internet speeds allow machines and systems to “talk” to each other in real time.

Together, these technologies create a seamless system where machines, computers, and humans collaborate to optimize production.

How Do Smart Factories Work?

Four easy steps can be used to understand how a smart factory operates:

IoT sensors installed on machines gather precise data, including vibration, speed, energy consumption, temperature, and pressure. A sensor could identify whether a motor is operating hotter than normal, for instance.

Processing Data:

Computers, either on-site (edge computing) or in the cloud, receive this data for analysis. Patterns and anomalies are detected by the system.

AI-powered decision-making systems assess the information and make recommendations. For instance, if maintenance is not done, the system can forecast that a particular equipment will probably break down within the next three days.

Automation and Action:

At last, the system takes action. It can deploy a robot to do corrective actions, notify employees, or automatically change machine settings. By doing this, the loop is closed and continual improvement is guaranteed.

Every second, this cycle is repeated, resulting in a production environment that is perpetually changing as robots pick up new skills and adjust.

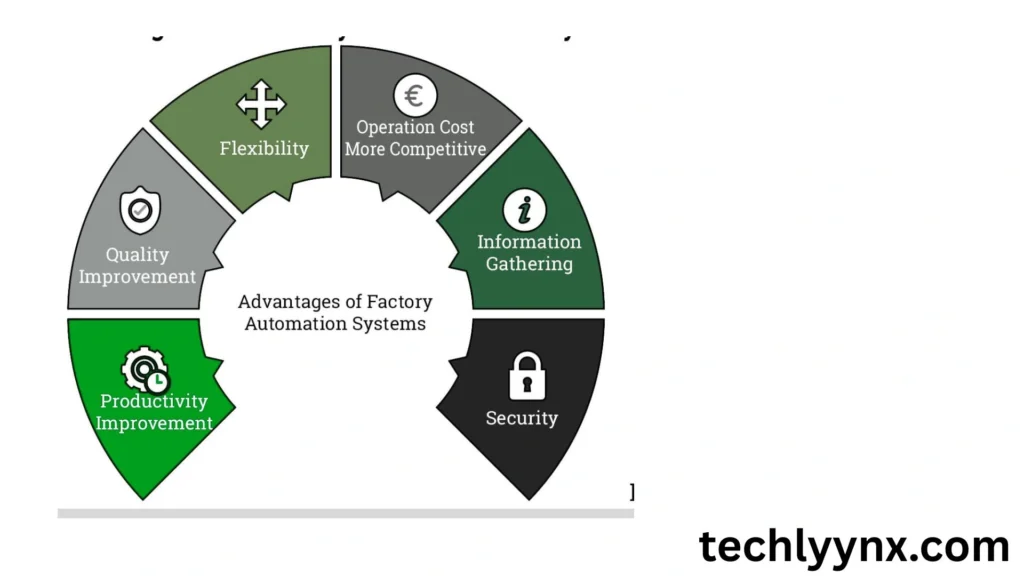

Advantages of Intelligent Factories

Companies from all over the world are drawn to smart factories because of their many advantages:

Increased Efficiency: Real-time monitoring optimizes productivity and minimizes delays.

Savings: Predictive maintenance prevents costly malfunctions and reduces repair expenses.

Improved Quality Control: Automated quality inspections reduce mistakes and subpar goods.

Flexibility: Manufacturing facilities can quickly transition between different products.

Sustainability: Eco-friendly production is supported by smart factories that consume less energy and generate less trash.

Employee safety: Humans concentrate on higher-value labor while robots tackle risky activities.

An automobile manufacturer, for instance, can use smart factories to increase production speed, personalize customer designs, and uphold high standards of quality.

Challenges

Despite their potential, smart factories also face obstacles:

- High Initial Investment: Setting up IoT sensors, AI systems, and robotics can be very costly.

- Cybersecurity Risks: Since everything is connected, hackers may try to disrupt systems or steal data.

- Skill Gap: Workers must be trained in digital tools, data analytics, and robotics, which requires time and investment.

- Compatibility Issues: Older machines in existing factories may not easily integrate with new smart technologies.

Companies must carefully balance these challenges with the long-term benefits.

Real-World Examples of Smart Factories

Some businesses now run smart factories on a worldwide basis:

- Siemens (Germany): Operates one of the most cutting-edge smart factories in the world in Amberg, where machines create nearly flawless machines.

- Tesla (USA): Increases the production of electric cars while maintaining excellent quality by using automation and real-time analytics.

- Samsung (South Korea): Uses AI and robots in electronics production to effectively satisfy demand worldwide.

These actual cases demonstrate that smart factories are not only hypothetical; rather, they are already influencing how things are made in the future.

The Future of Smart Factories

As we look to the future, smart factories will continue to advance well beyond the current automation levels. Machines will likely grow more self-sufficient in the future, with systems that can identify issues and fix them without assistance from humans.

As industries progressively incorporate renewable energy sources like solar and wind to lower their carbon footprint, sustainability will also become more important. AI-driven systems that can autonomously modify production plans in response to market demand, world events, or material shortages will make supply chains smarter and more flexible.

The way people and machines collaborate may be the most interesting development; humans will concentrate on creativity, invention, and decision-making, while robots will do hazardous or monotonous activities.

Conclusion

The core of Industry 4.0 is smart factories. They are ushering in a new era of manufacturing that is effective, adaptable, and sustainable by fusing IoT, AI, robotics, and real-time analytics.

The advantages—increased productivity, better quality, and long-term savings—make the shift valuable, despite obstacles like cost and cybersecurity.

To put it simply, a smart factory is more than just a location for manufacturing goods. It is a dynamic, learning system that combines data, people, and machines to enable more intelligent manufacturing.