This is our second post of banana peel research. Just according to our plan, now we will try to take a look at the tests and analysis that took place in our banana peel research. We have already discussed the basic steps and raw material preparation for further studies. Now this is the time to dig deep in our research. There are two tests involved in our banana peel research. The first one is Banana Peel Proximate Analysis, and the second one is called X-ray fluorescence analysis.

Banana Peel Research: Finding A Valuable Resource From Waste

In this post we will try to know what Proximate Analysis is, how it is performed, and what the results we got from the analysis are.

What is Proximate Analysis?

Proximate analysis is one of the most important analyses involved in chemical engineering. This is a well-known method to determine the basic compositions and nutritional facts of a substance. Typically used for the internal study of foods, vegetables, and other organic materials.

It provides a breakdown for different other processes. The processes involved in proximate analysis will be discussed step by step.

Components of Proximate Analysis.

There are some basic components of proximate analysis:

- Moisture Content:

The first test is of moisture analysis. In this test we determine the moisture or liquid content present in the sample substance.

- Ash Content:

The ash test is also a very important part of proximate analysis. The ash test is here to find the total mineral content after burning the substance completely.

- Crude protein test:

This estimates the crude content on the basis of nitrogen concentration using techniques like the Kjeldahl process.

We calculate this by difference, representing the remaining portion after accounting for moisture, protein, fiber, and ash.

Note!

In our studies we will just take a look at the first three tests.

- Moisture content

- Ash Content

- Volatile content

Moisture content: 1st in Proximate Analysis

Moisture content refers to the liquid content present in the material. We represent this as the percentage of its whole weight. It is also one of the critical parameters in proximate analysis.

Apparatus:

The apparatus we will use are the following in the chemical engineering lab named chemical process industries.

1- Drying oven (+105°C)

2- Weighing dish

3- Weight balance

Procedure:

- First of all, we dried the empty weighing dish along with its lid to constant mass.

- Weigh the weighing dish nearest to 0.1 mg.

- Add a minimum of 1 gram of the sample material in the dish.

- Placed this into the microwave oven first for 60 minutes.

- Dried it at least for 3 hours with a break period after every 60 minutes.

- After 3 hours, take the dish from the oven and instantly place it into the desiccator and let it cool at room temperature.

- After cooling, weigh the dish along with the sample immediately, as hygroscopic particles may cause disturbance.

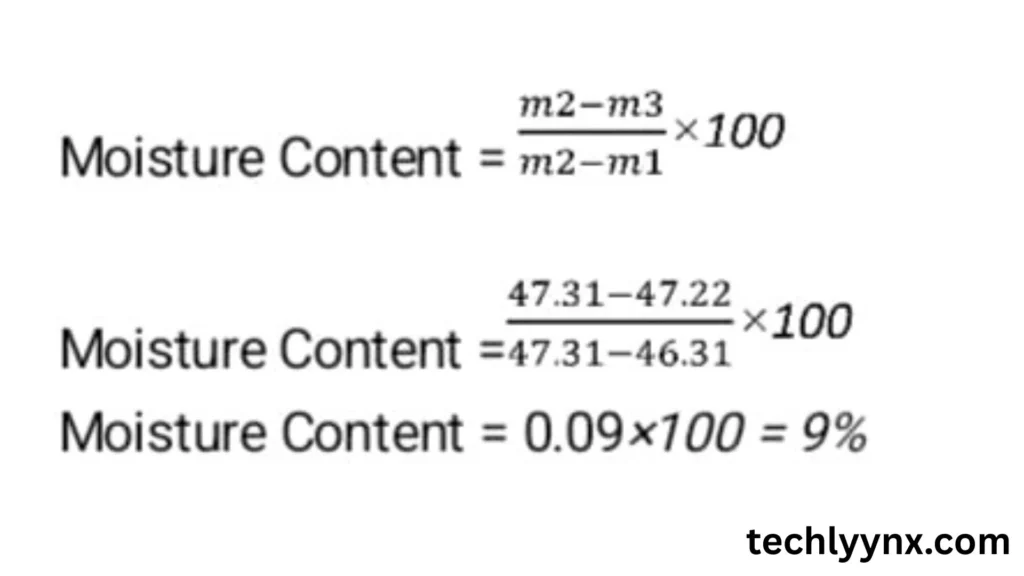

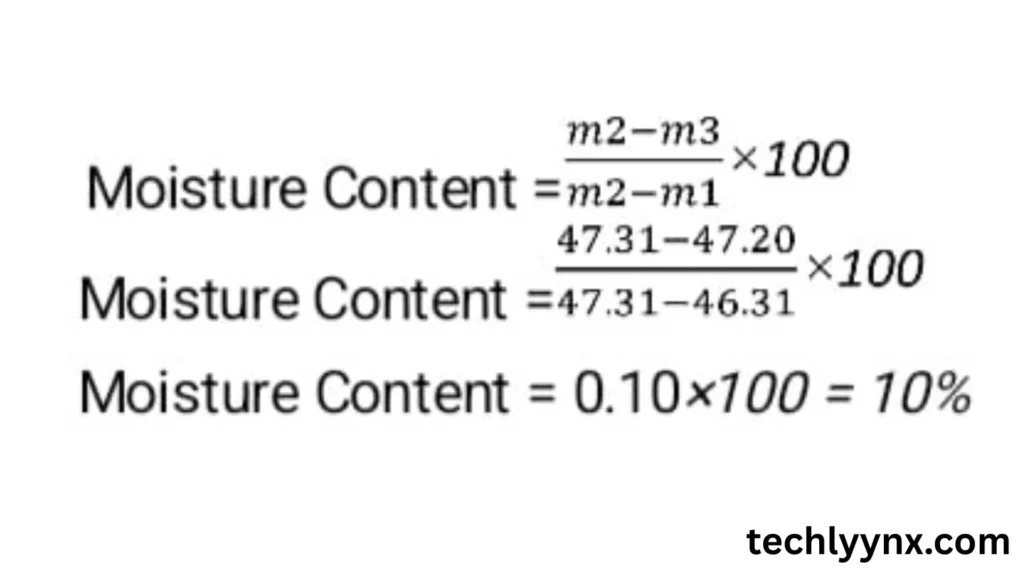

Calculations:

Weight of China Dish = 46.31 g

M2 = 47.31 g

M3 (After Heating) = 47.22 g

Weight of China Dish = 46.31 g

M2 = 47.31 g

M3 (After Heating) = 47.22 g

The mean value of the moiture content is 9.6.

Volatile Content:

Volatile content is the proportion of organic compounds and water present in a substance that is vaporized when at a high temperature.

This is also a very important quality factor in proximate analysis. This happens typically in the absence of oxygen.

Apparatus:

The apparatus we will use in this test is

1- Muffle Furnace (900+°C)

2- Thermocouples

3- Glass crucibles

4- Weight Balance

Procedure:

- Fill a stand with empty crucibles and insert it in the oven for 7 minutes.

- Remove the crucible from the furnace and let it cool in a desiccator or open environment.

- Weigh the cool empty crucible and lid.

- Put the sample material in the crucible and cover it with a lid; place it in the furnace again.

- After 30 minutes, get the crucible out, uncover it, and check whether it has formed a hard surface of material or not.

- If done, then place the crucible in the desiccator to cool it for some time.

- The experiment is complete; check out the product according to your expectations.

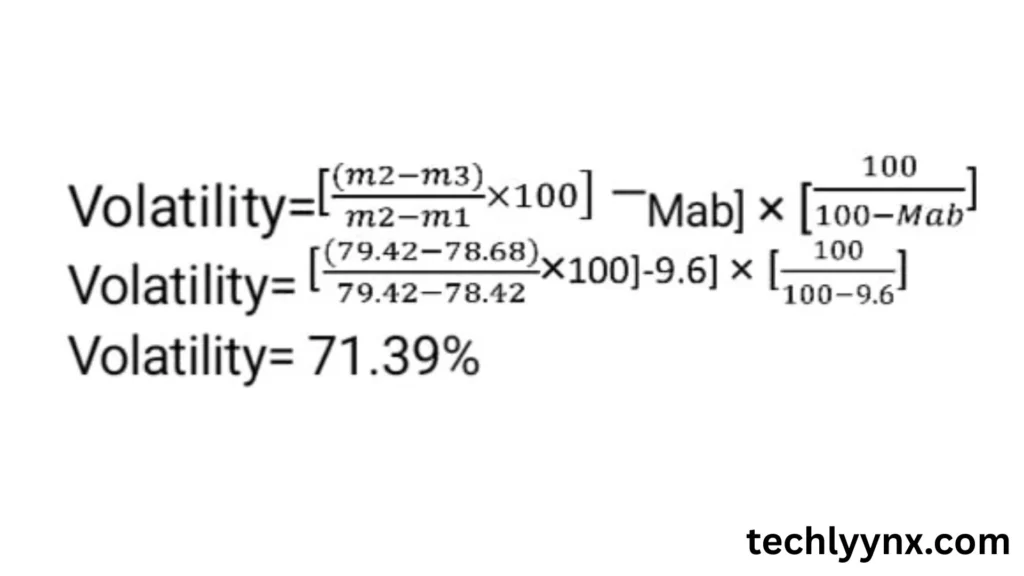

Calculations:

M1 = 78.42 g

M2 = 79.42 g

M3 ( After Heat) = 78.68 g

Ash Test: Very Important in Proximate Analysis

This is the last and third test in our proximate analysis of banana peel. The ash test is used to determine the inorganic, non-combustible material left behind after the complete combustion of the sample.

It provides information about the mineral content of the material.

Apparatus:

For ashing crucibles, 59 ml platinum crucibles we prefer.

- Microwave Oven

- Analytical Balance

- Vacuum Desiccator

- Muffle Furnace

Procedure of Ash Test in Proximate Analysis

- Weigh a known quantity of your pre-dried sample material.

- Place this into the ashing crucible and cover with its lid.

- Place the crucible with material in the stand and transfer to the muffle furnace at a temperature of 900+.

- Wait until the organic matter is all burned out.

- Take the sample out.

- Place it into the desiccator and allow it to cool at low temperature slowly.

- After cooling, get the product back and observe it.

Here came a twist when we had done all these experiments and got results.

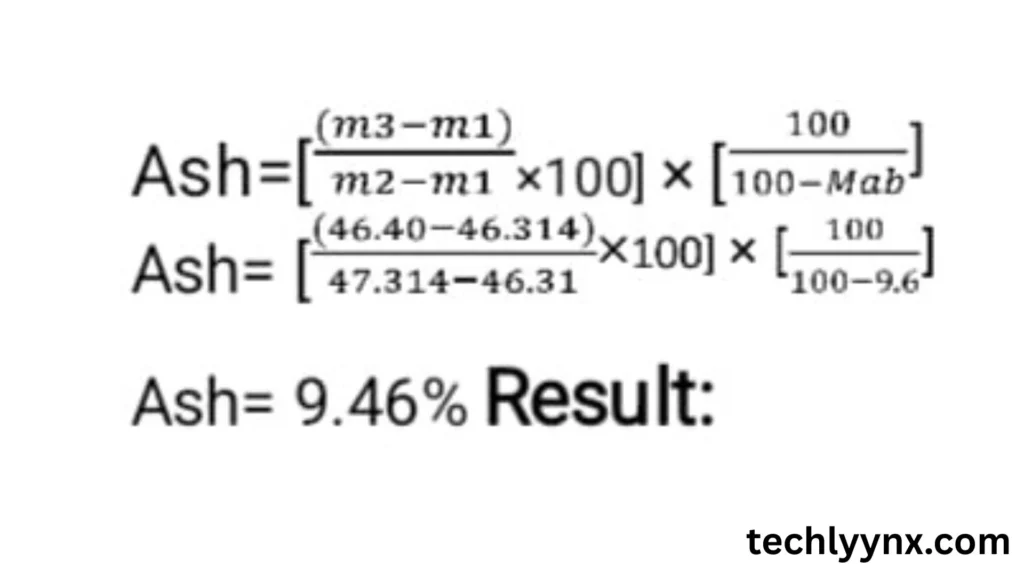

Calculations:

M1 = 46.31 g

M2 = 47.31 g

M3 (After Heat ) = 46.40 g

Final Twist in Proximate Analysis

This was the time of evaluation. I with my friends went to our instructor (Dr. Ansar Javed) and let him check our results. When my friend had passed the examination, the sir asked me to show the results. Unknown to me, the pages of the register got mixed, and I was late to get results. Sirr was in a hurry; he asked me to come after some time, which obviously I didn’t want. But I had to do it unfortunately and got late from reaching the hostel.

Next Post …