The Future of Mechanical Engineering represents not only an evolution of traditional machinery and design but also a complete transformation of the discipline into a digitally enabled, sustainability-driven, and innovation-focused domain.

The classical scope of mechanical engineering has always included thermodynamics, fluid mechanics, kinematics, and materials science. However, the growing complexity of modern industry shows a steady integration of artificial intelligence, smart manufacturing, renewable energy, and computational simulation into the very core of mechanical practices.

Mechanical Engineering Innovations That Changed the World

The expectations for the future of mechanical engineering go beyond simple technological advancements. The profession is responsible for tackling global energy demands, environmental difficulties, mobility needs, and healthcare improvements. The future emphasizes mechanical engineers’ roles as problem solvers, innovators, and contributors to human progress throughout industries and societies.

Technological Trends in the Future of Mechanical Engineering

Automation and Robotics

Automation continues to play a vital role in the future of mechanical engineering. Robotics uses range from car assembly to medical operations. Advanced robotic systems combine accuracy, adaptability, and efficiency. Collaborative robots (cobots) provide safe engagement with human workers, while robotic process automation decreases human error and costs. The dominance of robots reflects a significant transition from manual intervention to digitally guided systems.

Additive Manufacturing and 3D printing

Additive manufacturing is a groundbreaking innovation. Mechanical engineers use 3D printing to create speedy prototypes, bespoke products, and lightweight structural designs. The Future of Mechanical Engineering includes full acceptance of 3D printing in aerospace, automobile, and medical implant industries. Complex lattice patterns, on-demand spare part fabrication, and reduced material waste all increase the utility of additive technologies.

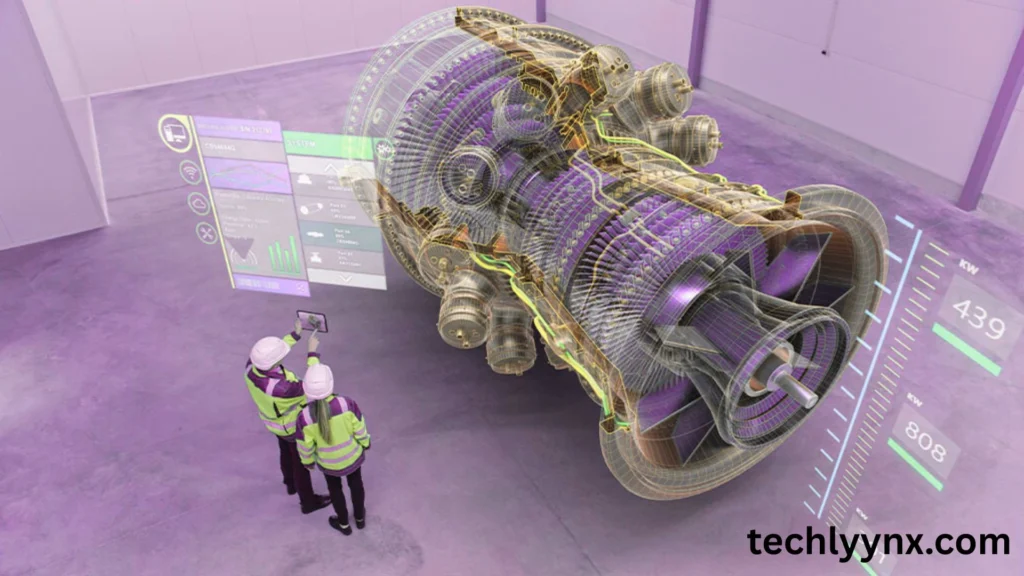

Digital Twin and Simulation

The use of digital twin technology offers predictive analysis capabilities. A digital twin provides a real-time mirror of a physical system, enabling continuous monitoring, optimization, and predictive maintenance. In the future of mechanical engineering, the digital twin will be a regular tool for power plants, transportation systems, and large-scale industrial equipment.

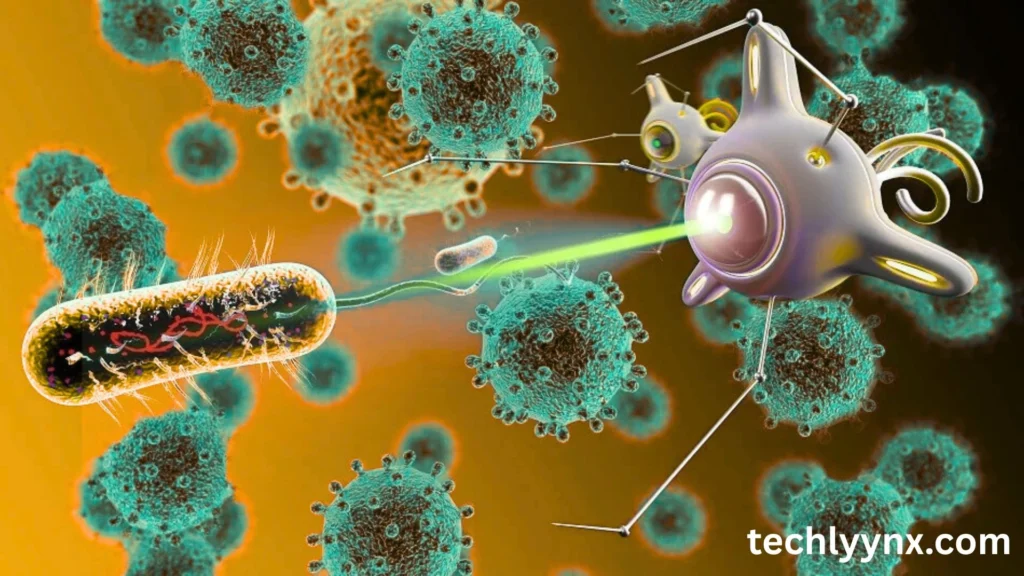

Smart Materials and Nanotechnology

Mechanical engineers investigate the applications of shape-memory alloys, piezoelectric materials, and nanocomposites. These materials respond to stimuli such as heat, stress, and electricity. The Future of Mechanical Engineering demonstrates the widespread use of such smart materials in aerospace, defense, and healthcare applications. Nanotechnology helps to create ultra-lightweight cars, stronger materials, and effective thermal management systems.

AI and Data Analytics

Mechanical engineering is increasingly reliant on artificial intelligence and machine learning. Data-driven design optimization, system health monitoring, and automated quality control become necessary. AI ensures defect prediction before a failure occurs, while machine learning enables intelligent control of industrial operations.

Sustainability Expectations in the Future of Mechanical Engineering

Renewable Energy Engineering

Mechanical engineers make significant contributions to the design of wind turbines, geothermal energy systems, and solar collectors. The future of mechanical engineering includes the dominance of renewable energy systems in terms of global energy security.

Green Manufacturing and Energy Efficiency

Sustainable manufacturing needs energy-efficient machines, reduced resource usage, and the implementation of environmentally responsible methods. Lean manufacturing processes, recycling, and closed-loop production lines all help to reduce industrial waste and emissions.

Circular Economy Integration

The circular economy ideas have a direct connection to the future of mechanical engineering. Engineers prioritize designs that enable product reuse, remanufacturing, and recyclability. Lifecycle analysis has become an important technique for assuring the sustainability of products and systems.

Sustainable Mobility

Electric vehicles, hybrid propulsion systems, and lightweight materials remain at the center of transportation engineering. Mechanical engineers play a vital role in battery efficiency, drivetrain improvement, and aerodynamics optimization. Sustainable mobility reduces dependence on fossil fuels while supporting clean transportation development.

Industry and Workforce Transformation

Interdisciplinary Collaboration

The Future of Mechanical Engineering encourages collaboration across disciplines. Mechanical engineers work alongside computer scientists, electrical engineers, chemical engineers, and biological researchers. This interdisciplinary approach drives innovation in driverless vehicles, medical robots, smart industries, and renewable energy systems.

Computational proficiency

Modern mechanical engineering necessitates advanced computational modeling skills. Virtual prototypes can be created using finite element analysis (FEA), computational fluid dynamics (CFD), and multiphysics simulation, which reduces costs and development time.

Global Industry 4.0 Transition

The global shift to Industry 4.0 is based on cyber-physical systems, cloud manufacturing, and Internet of Things (IoT) connection. The Future of Mechanical Engineering responds to these trends by focusing on digital literacy, simulation-driven design, and intelligent system integration.

Workforce Expectations

Future engineers require adaptability, creativity, and lifelong learning capacity. The profession demands expertise not only in core mechanics but also in data science, sustainability practices, and ethical responsibility. Professional development through continuous skill training ensures relevance in dynamic industries.

Challenges in the Future of Mechanical Engineering

- Skill Gaps: Universities may struggle to provide updated curricula that match rapidly advancing industry requirements.

- Environmental Responsibility: Balancing sustainability with industrial productivity creates constant tension.

- Global Competition: Engineers face pressure from international markets and technological disruption.

- Ethical Concerns: Autonomous systems and AI-driven decision-making raise issues of accountability.

- Resource Scarcity: Limited availability of rare-earth materials affects design strategies.

Opportunities for Innovation

Biomedical Engineering & Healthcare

Mechanical engineers develop prosthetics, implants, surgical robots, and medical imaging equipment. According to The Future of Mechanical Engineering, mechanical engineering will play an increasingly important role in healthcare development.

Aerospace and Space Exploration

Aerospace innovation potential include lightweight composite materials, efficient propulsion systems, and thermal protection structures. Mechanical engineering skills are critical for space colonization and satellite technology development.

Smart Infrastructure and Urban Systems

Engineers create efficient HVAC systems, automated building structures, and renewable-powered cities. Urban sustainability is dependent on mechanical system innovation.

Micro and Nanoengineering

Miniaturized mechanical systems are used in sensors, actuators, and microelectromechanical devices (MEMS). The integration of nanoscale gadgets into mechanical systems broadens technological possibilities.

Educational Evolution

The Future of Mechanical Engineering requires transformation of education. Universities emphasize project-based learning, interdisciplinary projects, and computational skills. Curricula integrate sustainability, ethics, and global engineering perspectives. Continuous professional development programs provide updated knowledge for industry professionals.

Conclusion

The Future of Mechanical Engineering represents a transition in technology, sustainability, industry, education, and society. The discipline has evolved from typical machine-focused applications to a diverse realm that includes robots, renewable energy, artificial intelligence, and smart materials. The trends include automation, additive manufacturing, and digital twins, while the expectations are for sustainability, efficiency, and interdisciplinary collaboration.

The opportunities outweigh the challenges, ensuring that mechanical engineering remains a source of innovation. Engineers of the future must be adaptable, creative, and ethically responsible. Mechanical engineering will maintain its place as a primary driver of industrial progress, global sustainability, and human development.